For many manufacturers, choosing between available stock equipment and waiting for custom material handling equipment has become a familiar dilemma. While standard machinery may seem quicker or cheaper, production equipment is a decades-long investment. The wrong fit can mean inefficiency, higher costs, and safety risks that compound over time.

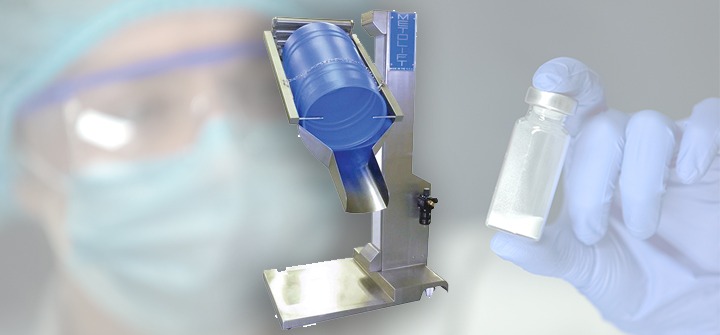

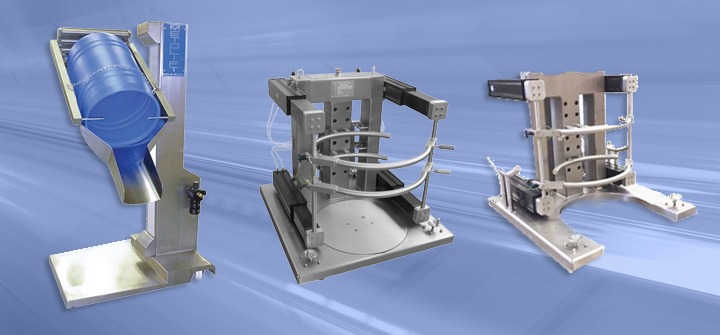

Drum handling equipment, including drum dumpers, tilters, and tippers, ensures the safe, reliable, and controlled transfer of bulk materials from drums into downstream processing equipment or storage vessels. The right drum handling solutions can mitigate processing issues, enhance workplace safety, and boost productivity.

The current state of the supply chain has caused consumers and business buyers to consider whether to wait for what they want to become available or settle for a product that is below their usual standard. If, for example, you are in the market for a new car, you have probably experienced this firsthand.

Drum Dumpers and Tippers are ideal for charging coaters; filling hoppers, reactors, and other process vessels; dispensing applications; and discharging powders, granules, pellets, and tablets.

Tippers position the drum downward, allowing the product to be easily discharged through a bung in the head of the drum.

Tippers position the drum downward, allowing the product to be easily discharged through a bung in the head of the drum.

As commonplace as drum manipulation is in today’s industrial workplaces, choosing the wrong type of drum handling equipment can become a very costly mistake. Special lifting devices make it easy to pick up, tilt, rotate, and transport drums. This drum manipulation equipment not only protects employees from physical harm, but also increases the efficiency of the workflow as a whole.

Large, heavy drums can be cumbersome and even hazardous to maneuver. Having the proper drum handling equipment can mean fewer accidents and a safer work environment for your employees. In this article we will discuss METO Systems’ drum handling equipment along with some of their benefits.

In general, drum handling equipment is specially designed to make the movement and work concerning heavy drums as effortless, safe, and time efficient as possible.

In general, drum handling equipment is specially designed to make the movement and work concerning heavy drums as effortless, safe, and time efficient as possible.