In industries such as pharmaceuticals, fine chemicals, and nutraceuticals, precision in dry processing and bulk solids handling is critical. Consistency, safety, and product quality depend on advanced blending technology that can keep up with evolving production demands. Companies are increasingly investing in automated and reliable systems to ensure efficient workflows, safeguard materials, and maintain the highest levels of compliance.

At the heart of these processes is mixing and blending—a fundamental step that ensures homogeneity across raw materials, intermediates, and finished products. From small-scale R&D to large-scale production, METO Systems delivers equipment designed for efficiency, safety, and reliability.

If your business is expanding capacity, replacing outdated machinery, or seeking to improve production quality, METO Systems offers a wide range of blending solutions engineered for long-term performance.

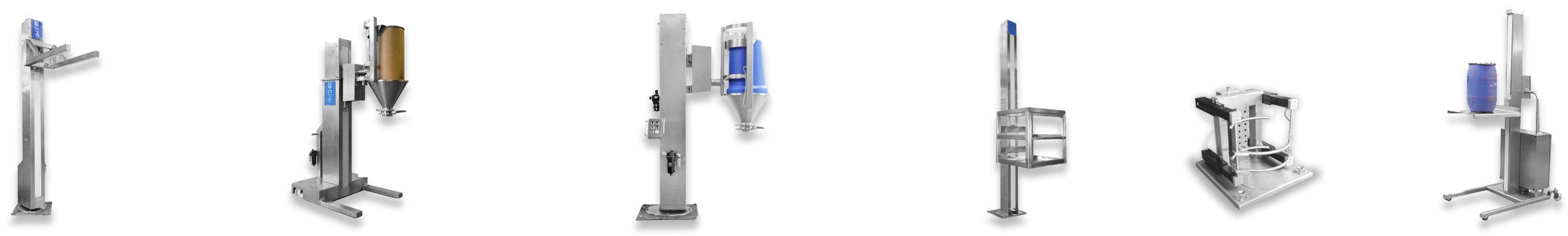

Lab Scale Blenders

Lab Scale Blenders are ideal for pharmaceutical, chemical, and food applications requiring small-batch precision. METO’s stainless-steel units replicate the function of full-scale systems but are sized for containers up to 5 cu. ft. Compact and mobile, these blenders include locking swivel casters and floor leveling locks for secure, efficient operation in lab environments.

Drum Blenders

Drum Blenders are a practical solution for suspending liquids, breaking up powder clumps, or mixing ingredients. Unlike conventional drum rollers, METO’s tumblers rotate drums end-over-end rather than around the center axis. This creates more robust agitation and eliminates the need to lay drums on their side, improving safety and consistency.

Bin Blenders

Bin Blenders—also known as IBC Blenders or Pharmaceutical Powder Blenders—integrate advanced PLC and variable frequency control technologies. These systems automate clamping, lifting, mixing, and lowering actions, ensuring consistency while reducing manual handling.

Bin Blenders also:

- Prevent product exposure and cross-contamination.

- Save floor space by combining blending, lifting, and positioning in one system.

- Allow direct discharge to the next process stage without additional handling.

- Feature fail-safe lift mechanisms to maintain stability during power loss.

Their versatility makes them ideal for handling high-potency materials and streamlining production.

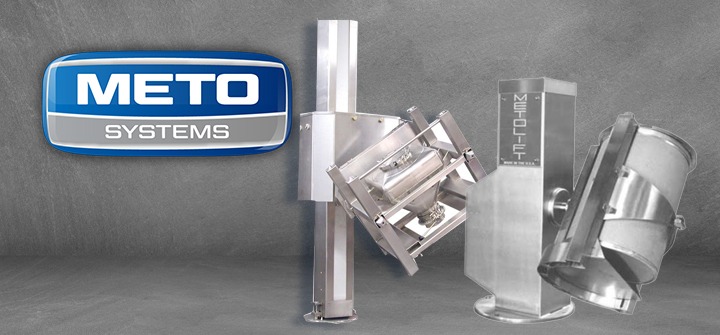

Column Blenders

Designed to receive, lock, lift, and blend Intermediate Bulk Containers (IBCs), Column Blenders eliminate material transfer between machines—reducing segregation, cross-contamination, and product loss.

- Small Stationary Column Blender – Supports containers up to 0.5 cubic meters. Built with stainless steel and laser-scanner safety features, it handles multi-sized portable containers within a consistent footprint.

- Production Stationary Column Blender – Accommodates larger IBCs up to 1.5 cubic meters. Fail-safe lift mechanisms ensure secure operation, while optional rotational columns provide precise positioning.

Both systems blend at adjustable speeds of 1–20 rpm, with either top or side support for maximum flexibility.

Why Choose METO Systems?

Every METO blending equipment is engineered for long-term reliability and is delivered as a complete, ready-to-use package with minimal on-site assembly. Our expert engineering and service teams provide ongoing support for upgrades, maintenance, and spare parts.

With robust construction, advanced safety features, and designs tailored to the unique needs of pharmaceutical, fine chemical, and nutraceutical production, METO’s equipment ensures your dry processing and bulk solids handling operations are built for the future.

📞 Contact our sales team at 201-405-0311 or visit our contact page to learn more about how METO Systems can support your blending and processing needs.

About METO Systems

For over 50 years, METO Systems has been a leading supplier of process and material handling equipment for various industries, including Pharmaceuticals, Fine Chemicals, Nutraceuticals, and Food. Our dedicated staff is here to support you with all your engineering design and installation questions.