In modern powder processing, IBC bin blending has emerged as a preferred solution for industries seeking higher efficiency, improved hygiene, and better blend integrity. Compared to traditional fixed-shell blenders such as V-cone, double-cone, or ribbon mixers, IBC blenders deliver operational flexibility, faster changeovers, and a cleaner manufacturing process.

How IBC Bin Blending Works

An Intermediate Bulk Container (IBC) serves as both the blending vessel and the storage/transfer container. Powders are charged directly into the IBC, which is then secured into a bin blender drive unit. The container is rotated according to a programmed blend cycle, ensuring uniform mixing. Once complete, the same IBC can be transferred directly to the next stage in production without intermediate handling.

Key Advantages of IBC Bin Blending

- Single-Container Processing

- Eliminates the need to transfer materials in and out of a fixed blender.

- Reduces handling steps, contamination risks, and product losses.

- Reduced Residual Waste & Dust Emissions

- Minimal powder remains in the container after discharge.

- Less airborne dust improves workplace safety and reduces cleaning frequency for surrounding areas.

- Faster Changeovers

- Cleaning is required only for the IBC in use.

- Multiple IBCs can be prepared in advance to enable rapid batch switching without downtime.

- Space Optimization

- No large, permanently installed blending vessel is required.

- Compact drive stations can be installed in flexible locations for better plant layout.

- Maintaining Blend Uniformity

- The blend remains in the same sealed container until discharge.

- Prevents particle segregation and protects product quality.

Typical Applications

IBC bin blenders are widely used in:

- Pharmaceutical manufacturing — maintaining GMP compliance while minimizing cross-contamination.

- Nutraceutical production — ensuring precise dosage homogeneity.

- Food and beverage powders — protecting sensitive ingredients from moisture and contamination.

- Chemical powders — reducing dust exposure and ensuring consistent material properties.

METO’s IBC Bin Blending Solutions

METO Systems’ full-sized IBC Blending System is a stationary column blender designed for containers up to 1.5 cubic meters. Constructed from durable stainless steel, this floor-mounted blender offers both top or side support options. It efficiently blends products in round or square containers with a variable speed drive ranging from 1 to 20 RPM.

Our blenders can be customized to integrate seamlessly with your existing bins, with height and reach tailored to your specific application needs. Fail-safe lift mechanisms securely hold the platform in place without drift—even during power loss. Additionally, an optional rotational column allows for precise positioning of the container for optimal blending performance.

Features include:

- Programmable blending cycles with adjustable rotation speed and angle.

- Automated locking mechanisms for safety during operation.

- GMP-compliant stainless-steel construction for hygienic environments.

- Integration with upstream and downstream equipment such as filling lines, weighing stations, and discharge systems.

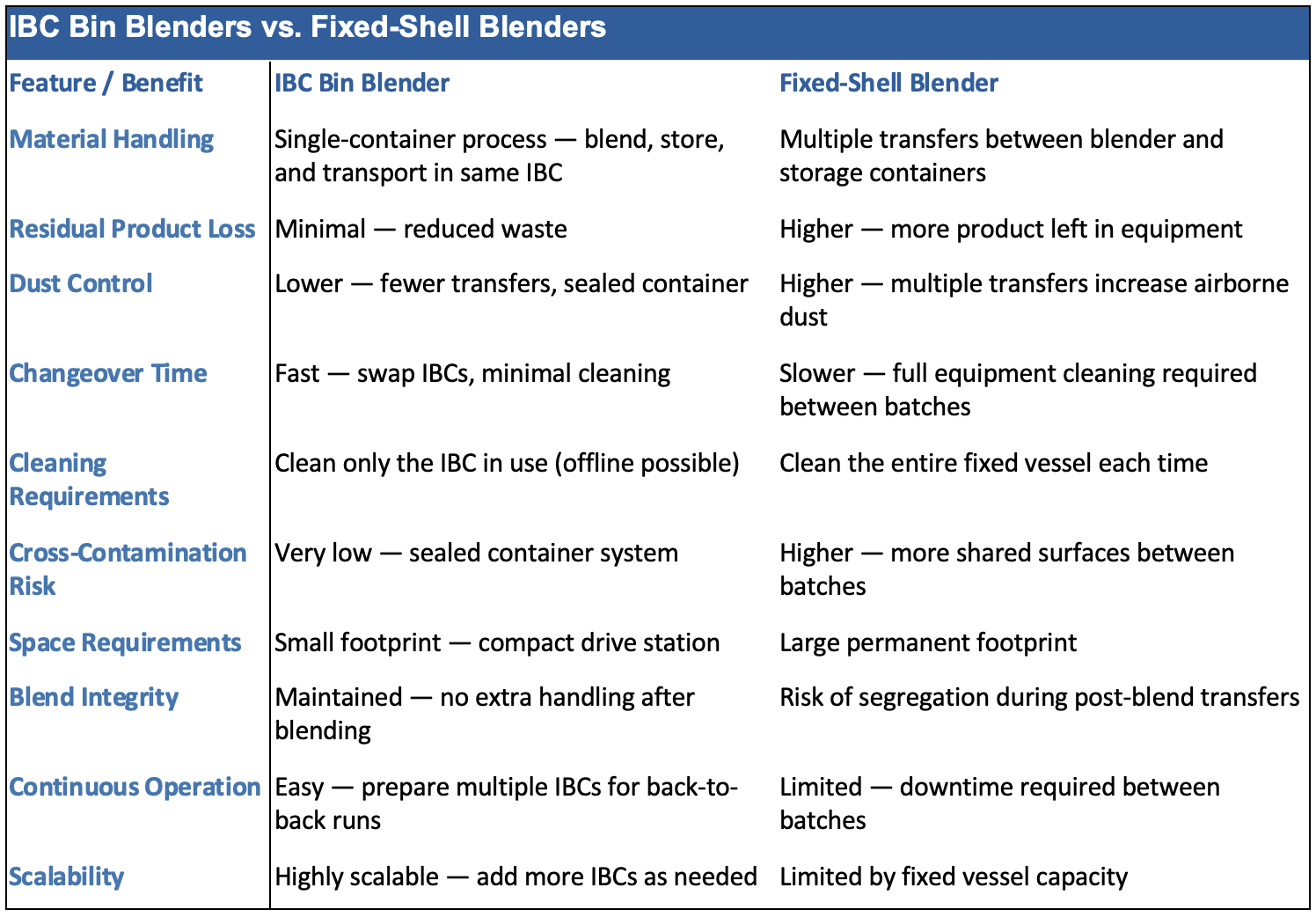

IBC Bin Blenders vs. Fixed-Shell: Key Differences

Fixed-shell blenders have been the industry standard for many years, known for their durability and effectiveness in mixing powders within a fixed, enclosed vessel. They are ideal for batch processing where the material is loaded, mixed, and discharged in separate steps. However, these blenders often require significant manual handling or additional equipment to transfer materials, which can increase processing time and labor costs.

In contrast, IBC bin blenders integrate the container itself into the blending process, allowing for easier loading, blending, and unloading without the need for extra transfer steps. This innovation can improve efficiency, reduce contamination risk, and simplify sanitation.

The following table highlights key differences between fixed-shell blenders and IBC bin blenders to help you understand which solution best fits your application.

Why Choose METO?

- Engineering expertise — Over 50 years of designing process and material handling equipment.

- Custom configurations — Tailored to your specific throughput, space, and compliance needs.

- Global support — Installation, training, and after-sales service worldwide.

Upgrade your powder processing with METO’s IBC bin blending technology. Contact our team to discuss your application and discover how we can help you achieve higher productivity, improved product quality, and lower operating costs.

About METO Systems

For over 50 years, METO Systems has been a leading supplier of process and material handling equipment for various industries, including Pharmaceuticals, Fine Chemicals, Nutraceuticals, and Food. Our dedicated staff is here to support you with all your engineering design and installation questions.