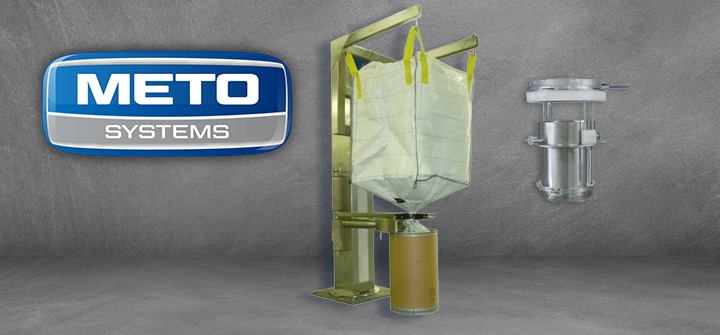

Flexible Intermediate Bulk Containers (FIBCs), or bulk bags, remain an industry-standard solution for the clean, efficient transport and storage of dry materials—ranging from resins and powders to seeds, granules, and pharmaceutical ingredients. Their flexibility, reusability, and low environmental impact make them ideal for sectors with high demands for performance and sustainability.

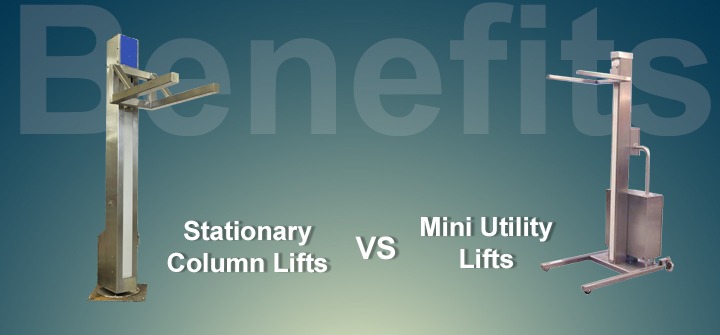

For smaller-scale, lightweight applications, METO Systems offers the Mini Utility Lift series. These versatile lifts, designed to handle loads up to 500 lbs., are ideal for tight spaces without obstructing neighboring equipment.

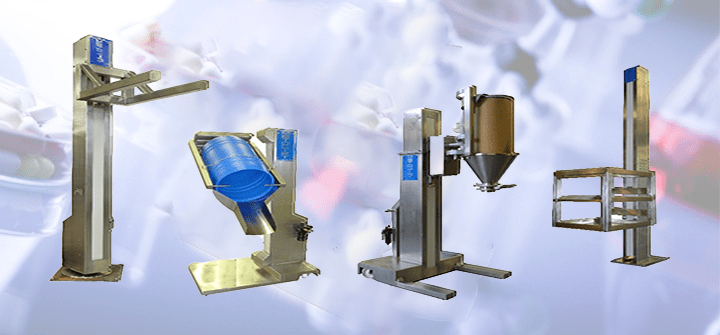

Operational efficiency and safety are paramount in the dynamic landscape of material handling requirements. Whether you are elevating process equipment to take advantage of gravity, moving material to storage, or moving product between process points, there is a need for robust, easy-to-operate, safe, and operationally repeatable vertical handling equipment.

Efficient material handling is crucial in the pharmaceutical, nutraceutical, and food processing industries, where precision and hygiene are paramount. In this article, we will compare and contrast stationary column lifts and mini utility lifts, evaluating their suitability for use in these industries.

Efficient material handling is a cornerstone of productivity across industries. The right equipment can significantly improve workflow efficiency, enhance safety, and reduce labor costs. In this article, we will explore three types of material handling equipment: drum tilters, FIBC (Flexible Intermediate Bulk Container) column lifts, and drum blenders, and showcase their diverse applications in various industries.

Blending is a critical process in many industries, including food, pharmaceutical, nutraceutical, cosmetic, and chemical, to name a few. It comes with the risk of inconsistency, cross-contamination, product exposure, and loss but METO Systems brings you a range of efficient stainless-steel blenders that ensure the process occurs quickly, safely, and hygienically.

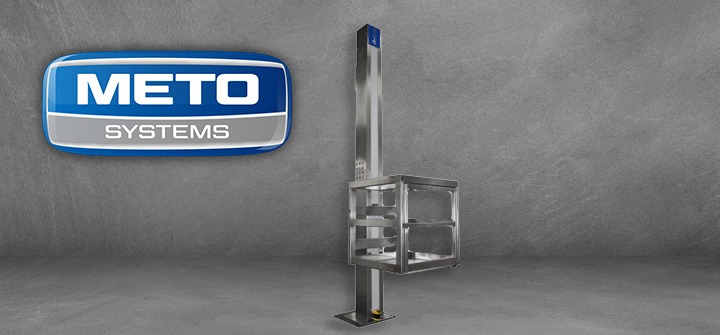

Platform lifts, also known as stationary column lifts, are a smooth, efficient way to move products, containers, tools, and equipment to various locations in a manufacturing facility. They can reach separate floors, elevated charging chutes, and positions both above and below processing equipment. Our column lifts provide simple, reliable, ergonomic solutions that ensure the safety of the operator when heavy loads need to be lifted and handled.

FIBC (Flexible Intermediate Bulk Container) bags are highly durable and reusable. They are usually referred to as bulk bags and are used for the transportation of dry bulk goods such as fertilizers, plastic granules, seeds, resins, and powders. This makes them suitable for use in a wide variety of industries.

For more than 50 years, METO Systems has been a leading supplier of process and material handling equipment for the Pharmaceutical, Fine Chemicals, Nutraceuticals, and Food industries. We manufacture state-of-the-art, Current Good Manufacturing Practice (CGMP), stainless-steel material handling and processing equipment. All equipment is designed for a lifetime of reliable use, with minimal routine maintenance needed.

Many production or manufacturing tasks that require overcoming gravity to aid the process will require the use of vertical lifting equipment. In many instances, the process will call for a lift to elevate and position process equipment over downstream automatic ‘process equipment'. Choosing the right lift for a project involves analyzing the task at hand and partnering with the appropriate vendor who will deliver the safest, most efficient, and best-performing equipment in the market today.