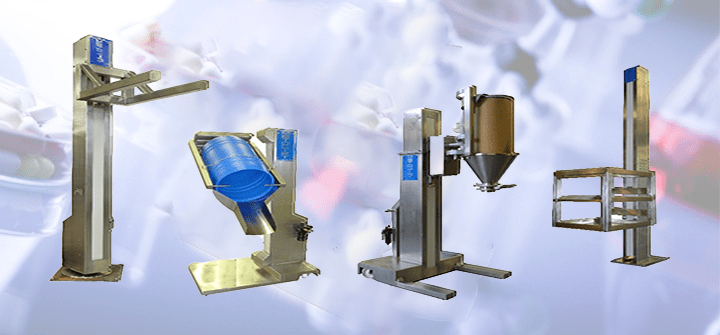

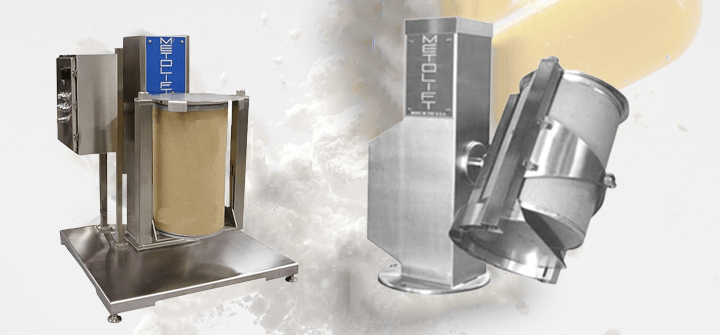

Drum Dumpers and Tippers are ideal for charging coaters; filling hoppers, reactors, and other process vessels; dispensing applications; and discharging powders, granules, pellets, and tablets.

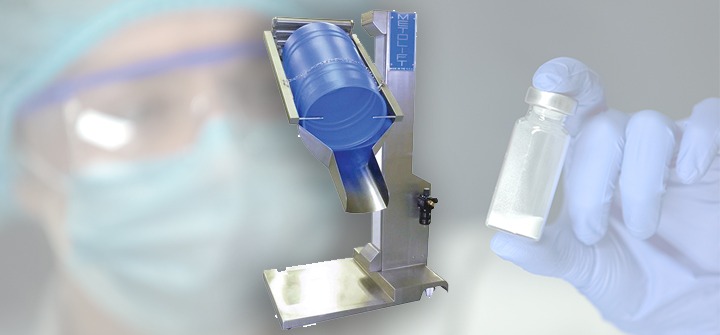

Tippers position the drum downward, allowing the product to be easily discharged through a bung in the head of the drum.

Tippers position the drum downward, allowing the product to be easily discharged through a bung in the head of the drum.