Blog

Top 10 Material Handling Solutions for Efficient Warehouse Management?

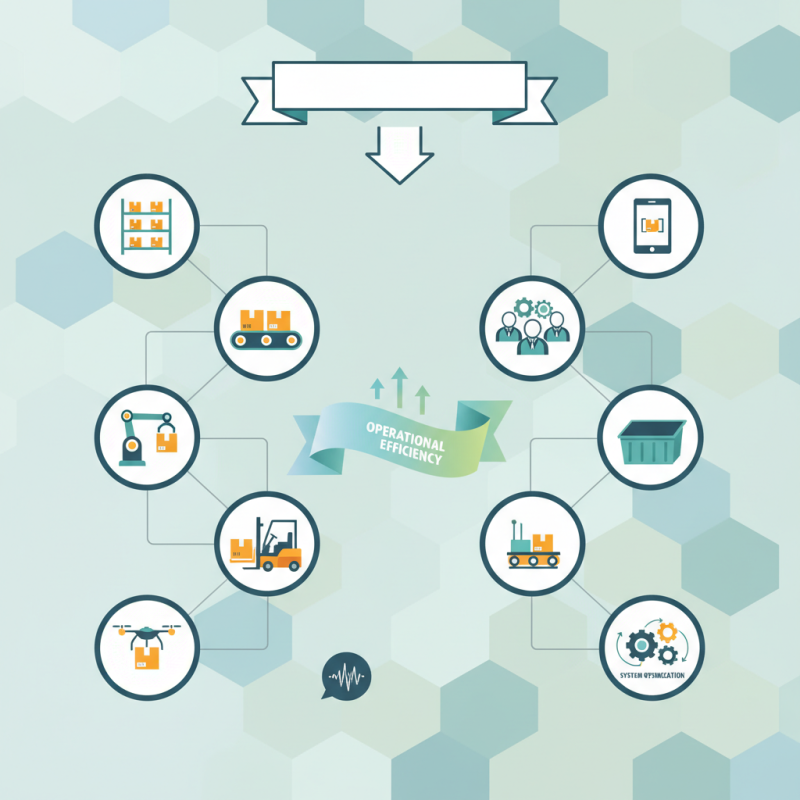

In the fast-evolving logistics sector, effective warehouse management is essential. The right material handling solutions can significantly boost operational efficiency. As expert John Smith, a leader in the material handling industry, stated, “The key to successful logistics lies in optimizing every process.” His insights challenge businesses to rethink their strategies.

Warehouse operations involve various moving parts. Whether it’s shelving systems or automated conveyor belts, each solution has its role. Sometimes, companies overlook the balance between cost and efficiency. Investing in high-tech solutions may seem appealing, but practicality must not be ignored. Simple measures, like improving staff training, can yield significant results too.

Choosing the best material handling solutions demands a deep understanding of specific warehouse needs. What works for one organization may not fit another. Firms must remain adaptable. Continuous reflection on these choices is crucial for sustained improvement. Small adjustments can create a ripple effect, enhancing productivity and accuracy in inventory management.

Top Trends in Material Handling Solutions for Warehouse Efficiency

In the fast-evolving world of warehouse management, efficiency is paramount. Companies are increasingly relying on innovative material handling solutions. Automation is a key trend. It helps streamline processes, reducing human error. Warehouse robots can transport goods swiftly, but they also face challenges. Integration with existing systems is often tough. This requires a thoughtful approach.

Another notable trend is the use of data analytics. By analyzing inventory levels and patterns, businesses can optimize operations. Predictive analytics can forecast demand, but inaccuracies can lead to overstocking or stockouts. It's a delicate balance. Additionally, ergonomic equipment is gaining attention. Investing in better tools for workers can enhance safety and productivity. However, many warehouses still use outdated methods, which can hinder progress.

Lastly, sustainable practices are becoming essential. Eco-friendly materials and energy-efficient machines attract attention. Warehouse spaces are utilizing vertical storage solutions to maximize floor space. This can be effective but may complicate access to stock. The path to efficiency is not straightforward. Each solution has its pros and cons, and careful thought is necessary before implementation.

Impact of Automation Technologies on Warehouse Material Handling

The rise of automation technologies is reshaping material handling in warehouses. Automated guided vehicles (AGVs) transport goods efficiently. They minimize human error and reduce labor costs. However, their deployment requires significant investment and ongoing maintenance. Keeping up with technology is challenging for many businesses.

Robotic systems streamline sorting and packaging tasks. They can work around the clock, increasing throughput. Yet, integrating these systems into existing workflows can be disruptive. Staff must adapt, and training is essential. Upfront costs can be a barrier, but the long-term savings often justify the investment.

Data analytics plays a crucial role as well. Real-time tracking and inventory management provide critical insights. It allows better decision-making but requires robust IT infrastructure. Many warehouses struggle with data security and system integration issues. Continuous improvement is necessary for effective implementation in the fast-paced environment.

Key Metrics for Evaluating Material Handling System Performance

Efficient warehouse management hinges on robust material handling systems. Key metrics play a critical role in evaluating their performance. Productivity is essential. Tracking units handled per hour helps gauge efficiency. It shows how well a warehouse utilizes its resources. A noticeable drop might indicate issues in the workflow.

Another important metric is accuracy. This includes picking accuracy and inventory accuracy. Mistakes can lead to lost sales and customer dissatisfaction. Measuring the rates of errors reveals weaknesses in the process. Teams can then focus on training and technology to enhance precision.

Cost-effectiveness is a deeper metric to scrutinize. Comparing operational costs against output helps identify efficiency gaps. If costs are rising without a corresponding increase in productivity, it’s time to reassess. Additionally, employee feedback can also provide insights. Are team members facing challenges with existing systems? Listening to their experiences could highlight areas in need of improvement.

Top 10 Material Handling Solutions for Efficient Warehouse Management

This bar chart illustrates the efficiency scores for various material handling solutions used in warehouse management. Each solution is rated out of 100, demonstrating their effectiveness in optimizing warehouse operations.

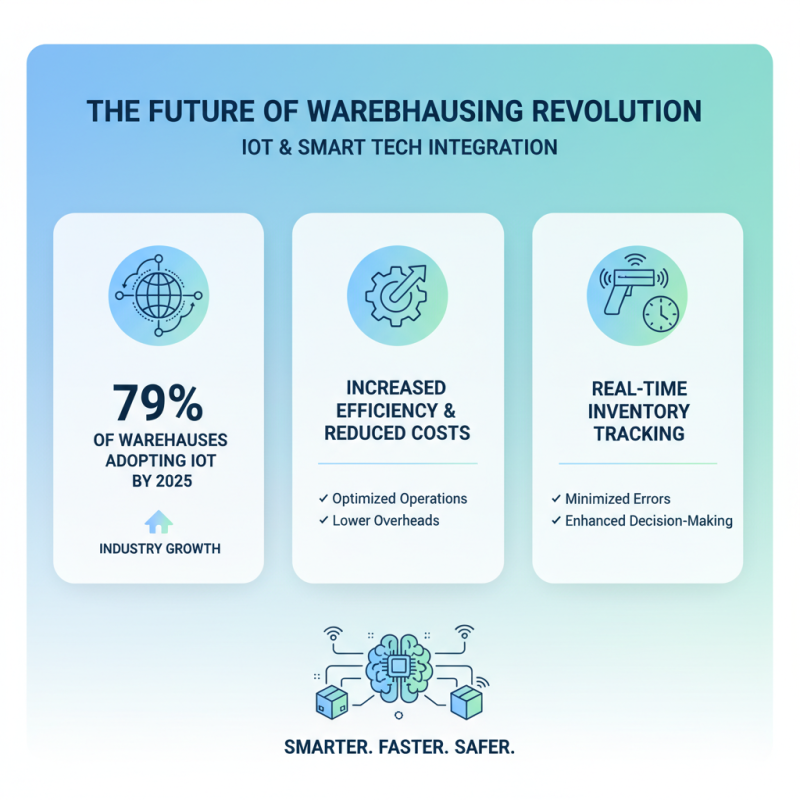

Integrating IoT and Smart Technologies in Warehouse Operations

The integration of IoT and smart technologies is revolutionizing warehouse operations. According to a recent industry report, 79% of warehouses are expected to adopt IoT solutions by 2025. This rapid adoption leads to increased efficiency and reduced operational costs. Real-time tracking of inventory enables immediate updates. It minimizes errors and enhances decision-making.

Automation is another critical aspect. Advanced robotics streamline processes, reducing manual labor. A study noted that automation can cut labor costs by up to 30% in some facilities. Many operations still rely on outdated methods. This results in slower processes and lost opportunities. Smart technologies shed light on bottlenecks, guiding improvements in workflows.

However, the challenges of integration must be acknowledged. Not all staff are equipped to handle new technologies. Training and development are essential. A report indicated that 48% of workers are not familiar with IoT applications. Addressing this knowledge gap is crucial. Investing in employee education fosters a smoother transition to a more efficient operation.

Benefits of Ergonomic Equipment for Reducing Workplace Injuries

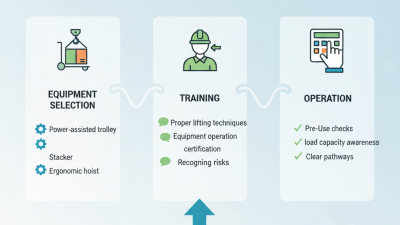

Workplace injuries can seriously impact productivity and morale. Ergonomic equipment plays a crucial role in preventing these injuries. When workers feel comfortable, they perform better. Tools designed with human factors in mind lead to less strain on the body.

Consider a warehouse filled with varied tasks. Workers lift, push, and pull heavy items daily. Without proper support, back pain and muscle issues can arise. Ergonomic solutions, such as adjustable shelving or lift assist devices, can ease this burden. These tools not only help reduce injuries but also improve efficiency.

Many warehouse managers still overlook ergonomics. They might focus solely on speed or cost-saving measures. However, neglecting worker comfort can lead to higher __absenteeism__ and increased injury claims. Investing in ergonomic solutions is not just about compliance; it’s about creating a sustainable work environment. When employees thrive, so does the bottom line.

Related Posts

-

Top Tips for Effective Drum Handling Techniques?

-

What is a Material Handling Cart and How Does it Improve Efficiency

-

Top 10 Best Material Hoists for Efficient Construction Projects in 2023

-

2026 Best Drum Tilters for Efficient Material Handling Solutions?

-

How to Choose the Right Material Hoist for Your Construction Project?

-

2025 Top Manual Handling Lifting Equipment Tips for Safe and Efficient Use