Blog

2026 How to Optimize Bulk Material Handling for Efficiency and Safety?

In the world of bulk material handling, efficiency and safety go hand in hand. As noted by industry expert Dr. James Patterson, "Optimizing bulk material processes reduces risk and enhances productivity." This insight emphasizes the critical need for improvements in handling methods.

The handling of bulk materials is often complex. Inefficient practices can lead to accidents and operational delays. For example, poorly designed conveyor systems may create bottlenecks or hazards. Companies must confront these challenges to maximize their effectiveness.

Adopting advanced technology is one way to enhance safety and efficiency. Automation and real-time monitoring can dramatically improve operations. However, without proper training and awareness, these innovations can pose new risks. Reflecting on past mistakes is essential for progress in bulk material handling. The journey to optimization is ongoing and requires persistent effort.

Understanding Bulk Material Handling Systems and Their Importance

Bulk material handling systems play a crucial role in various industries. These systems are essential for the transport, storage, and processing of bulk materials. They streamline operations and enhance productivity. With the right handling, companies can reduce costs and time on the production line.

Understanding these systems is vital. They are not merely about moving materials from point A to point B. Effective systems can minimize waste and ensure safety. For instance, poorly designed systems may lead to spills or accidents. This highlights the importance of proper planning and execution. Inadequate training for personnel can also pose risks. Training should focus on safety and efficient practices.

Improving these systems is an ongoing process. Regular assessments can reveal inefficiencies. Some operations might lack the latest technology. Others may need better maintenance routines. Identifying these gaps is essential for continuous improvement. Only by reflecting on these issues can companies enhance their operations and safety protocols.

2026 Optimization of Bulk Material Handling for Efficiency and Safety

This chart illustrates key factors in optimizing bulk material handling systems, highlighting the importance of increased productivity, reduced downtime, improved safety, cost efficiency, and enhanced material flow in the year 2026.

Key Factors Affecting Efficiency in Bulk Material Handling Processes

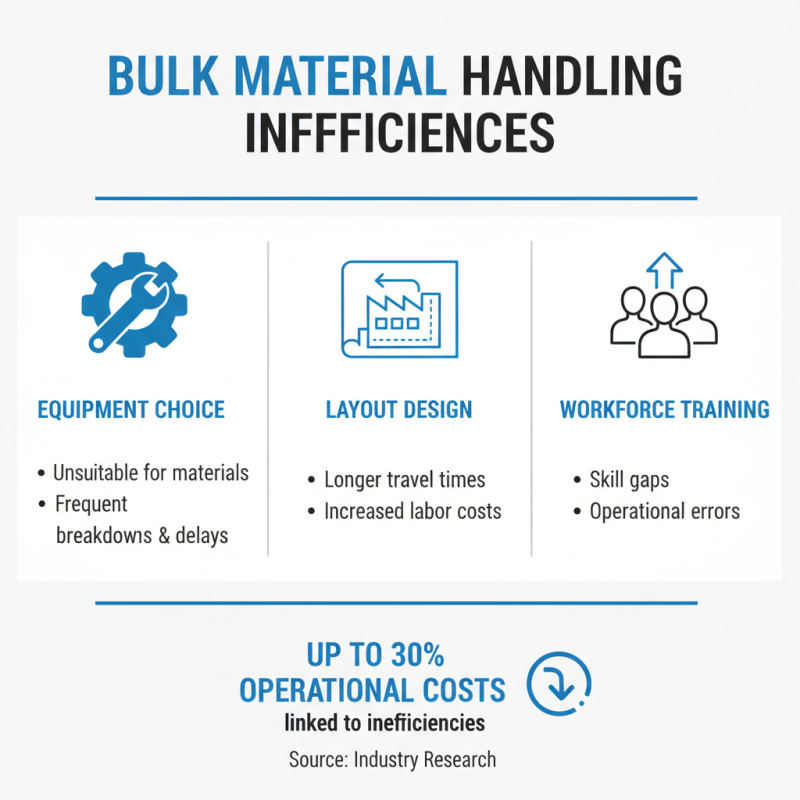

Bulk material handling is critical in various industries. Efficiency is often hindered by factors like equipment choice, layout design, and workforce training. Research indicates that up to 30% of operational costs are linked to inefficiencies in handling processes. Poor layout can lead to longer travel times and increased labor costs. Equipment that isn’t suited for the specific materials can result in breakdowns and delays.

Safety is equally important. Approximately 70% of workplace accidents are connected to improper material handling techniques. Ensuring proper training can reduce these incidents significantly. A study found that companies investing in training saw a 50% decrease in accidents related to material handling operations. Regular maintenance of equipment is another key factor. Neglect can lead to unsafe conditions and costly downtimes, further impacting efficiency.

Monitoring performance through data analytics is becoming essential. Many organizations are now utilizing sensors and tracking systems to analyze efficiency in real-time. However, these initiatives come with challenges. The initial investment can be substantial, leading to hesitation in implementation. Small-scale operations may struggle to adopt advanced technologies effectively. Addressing these challenges requires a balanced approach to optimize bulk material handling while maintaining safety and efficiency.

Safety Protocols and Best Practices for Bulk Material Handling

Bulk material handling requires strict safety protocols. Workers are often at risk due to heavy loads and machinery. Proper training is crucial. Employees must know how to operate equipment safely. Regular drills can help reinforce these lessons.

Personal protective equipment (PPE) is essential. Hard hats, gloves, and steel-toed boots should be standard. However, we must also assess whether workers wear them consistently. It's an ongoing challenge to ensure compliance. Machinery should have safety guards in place. These can prevent accidents, yet they are sometimes removed for convenience. This complacency can lead to serious injuries.

Regular inspections of equipment can identify potential hazards. It’s easy to overlook small issues. Minor problems can escalate if left unaddressed. Supervisors should conduct these inspections consistently. Foster a culture of safety where employees feel comfortable reporting hazards. We must prioritize these practices to keep everyone safe in bulk material handling environments.

Innovative Technologies to Enhance Bulk Material Handling Efficiency

Innovative technologies are transforming bulk material handling. Automation is a key player. Automated vehicles navigate warehouses efficiently, reducing the need for manual labor. This not only speeds up the process but also minimizes human error. Sensors and IoT devices monitor material conditions in real-time, enhancing safety protocols. Alerts can be sent instantly, allowing for quick responses to potential hazards.

Another exciting advancement is the use of AI in logistics. AI algorithms analyze data to optimize routes for material transport. This results in less fuel consumption and improved delivery times. However, the integration of AI also presents challenges. Training staff to work with these new systems is essential but not always straightforward. Many companies struggle with this transition.

Additionally, robotic systems are increasingly common in sorting and packaging. They improve efficiency, but initial costs can be high. Companies must weigh the long-term benefits against upfront investments. Reflection on how to balance these technologies is crucial. Embracing innovation in bulk material handling is vital. However, it should be done thoughtfully to ensure safety and efficiency are never compromised.

Strategies for Continuous Improvement in Bulk Material Handling Operations

Optimizing bulk material handling requires vigilance and a commitment to continuous improvement. One essential strategy is regular training for staff. Educated workers are more aware of safety protocols. They can identify hazards before they become serious issues. Consistent training sessions help maintain a high standard of operation. Engaging employees in discussions about challenges they face can foster creative solutions. It’s vital to ensure that feedback is not only heard but acted upon.

Another strategy involves leveraging technology. Automation can streamline processes, reducing manual labor and minimizing errors. However, integrating new systems can be daunting. Employees may resist changes, fearing they will lose their jobs. Thus, introducing new technologies gradually can ease this transition. Monitoring performance metrics closely is crucial to gauge the effectiveness of these upgrades. Are the improvements in efficiency and safety as expected? Regular audits can reveal gaps in the process or areas needing adjustment.

Lastly, collaboration among departments can enhance bulk material handling practices. When teams share insights, they can create more effective workflows. However, silos can hinder communication. Addressing this requires openness and willingness to cooperate. Using project management tools can help break down barriers. A culture of support and shared purpose is essential. Continuous reflection on these practices ensures that improvements are not only implemented but also sustained over time.

Related Posts

-

How to Choose the Right Material Hoist for Your Construction Project?

-

Top Manual Lifting Equipment Trends You Need to Know in 2025

-

10 Essential Material Handling Tips for Increased Warehouse Efficiency

-

What is a Material Handling Cart and How Does it Improve Efficiency

-

Why Investing in Quality Drum Lifting Equipment Saves Time and Reduces Risks

-

Top Tips for Effective Drum Handling Techniques?