Blog

Top 10 Material Handling Solutions Tips for Efficient Operations

In the fast-paced world of logistics, efficiency is paramount. According to John Smith, a leading expert in material handling solutions, “Streamlined processes can significantly enhance operational productivity.” With over two decades in the industry, he emphasizes the need for effective strategies to manage materials. Companies face challenges daily, from high operational costs to limited storage space.

Material handling solutions play a critical role in addressing these concerns. Effective solutions not only optimize space but also improve workflow. For instance, automated systems can reduce manual labor, yet they require a careful assessment of existing processes. It's essential to reflect on what works and what doesn’t. Too often, businesses ignore small inefficiencies that add up over time.

By adopting innovative material handling solutions, organizations can transform their operations. The key lies in understanding each component of the workflow. Investing time in training staff and upgrading equipment yields long-term benefits. As companies strive for excellence, the right strategies can lead to significant gains in efficiency and productivity.

Understanding Material Handling: Importance and Benefits

Material handling is crucial in modern operations. Properly managed, it enhances efficiency. According to the Material Handling Industry of America, effective material handling can reduce operational costs by up to 20%. This shows significant savings for businesses that optimize their processes.

Improper material handling can lead to safety hazards. The Occupational Safety and Health Administration (OSHA) reports that one in ten workplace injuries involves material handling. These statistics highlight a need for better training and equipment. Workers should be equipped to handle materials safely and efficiently.

Adopting advanced systems can provide tangible benefits. Automated systems can reduce labor costs and improve accuracy. However, transitioning to automation may face resistance. Training staff is essential, but it can be time-consuming. It's crucial to address these challenges upfront. A proactive approach can lead to smoother transitions and better operational outcomes.

Identifying the Right Equipment for Optimal Material Handling

In an environment where efficiency is key, selecting the right material handling equipment can significantly impact operational success. Data from the Material Handling Industry reports indicate that organizations investing in tailored equipment experience up to a 25% increase in productivity. For example, automatic guided vehicles (AGVs) can streamline transportation processes in warehouses. However, they come with a steep initial cost and complexity in integration.

Choosing the proper equipment demands consideration of your specific needs. A one-size-fits-all approach may lead to inefficiencies. Some companies find themselves overhauling their systems due to improper equipment choices, wasting time and resources. Evaluating factors such as load size, frequency of movement, and workspace layout is crucial. Miscalculating these parameters can result in interruptions and increased labor costs.

Operational layouts also play a critical role. A poorly designed warehouse can hinder material flow, regardless of the equipment available. Many facilities realize only after implementation that they should have opted for different solutions. This reflects a common issue: assumptions made during equipment selection can lead to flawed outcomes. A comprehensive analysis can help prevent such mistakes and ensure that the right equipment supports seamless operations.

Top 10 Material Handling Solutions for Efficient Operations

This chart illustrates the importance of various material handling solutions in enhancing operational efficiency. The data represents the percentage impact of different equipment on overall material handling performance.

Implementing Automation to Enhance Efficiency in Operations

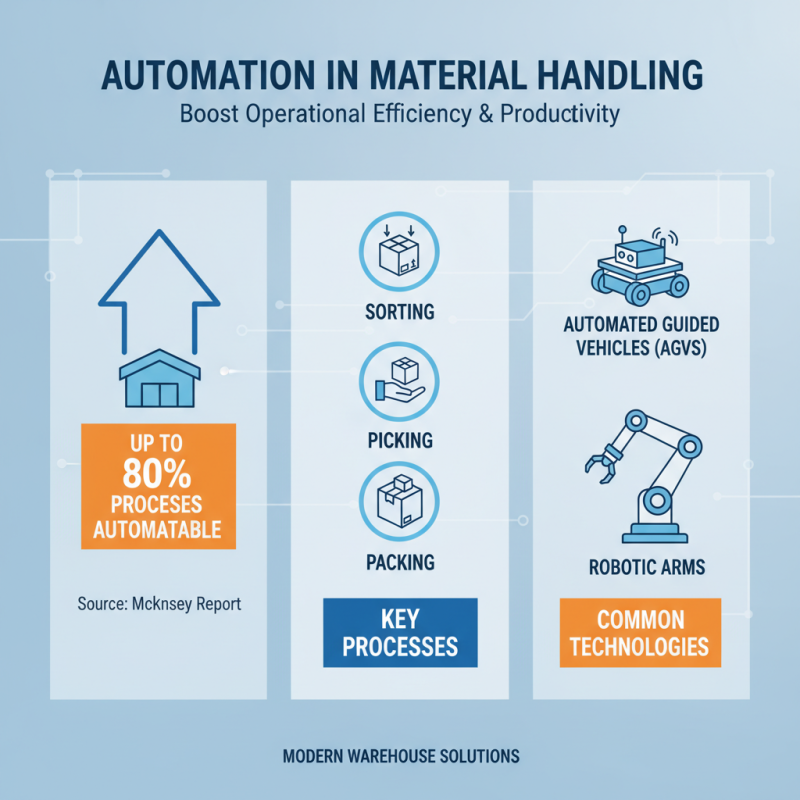

Implementing automation in material handling can significantly boost operational efficiency. According to a report by McKinsey, up to 80% of warehouse processes can benefit from automation. This includes sorting, picking, and packing. Automated guided vehicles (AGVs) and robotic arms are becoming commonplace in modern warehouses.

However, not all automation solutions fit every operation. An over-reliance on technology can lead to inefficiencies. For example, integrating automation without proper staff training can result in delays. A recent study indicates that 70% of automation projects fail due to insufficient workforce adaptation. It’s critical to tailor automation strategies to specific operational needs.

Analyzing data is essential. Many companies overlook the importance of tracking performance post-automation. Regular evaluations can reveal inefficiencies that were previously unnoticed. Automation should enhance workflows, not complicate them. Drivers of efficiency like reducing cycle times and improving accuracy are attainable through careful implementation. Nonetheless, the choice of technology requires thorough consideration and continuous refinement.

Training and Safety Measures for Effective Material Handling

Training and safety measures are vital in material handling operations. Workers must be equipped with the right skills. Regular training sessions help improve efficiency. It can also reduce accidents on the job. Employees should know how to operate equipment properly. Understanding the risks can prevent injuries.

One tip is to encourage open communication. Workers should voice concerns about safety. This creates an environment of trust. Another tip involves hands-on practice in real scenarios. Simulating tasks helps reinforce learning. Safety protocols should be clear and visible. Use visual aids to remind workers of safe practices.

Reflecting on past operations can unveil crucial areas for improvement. Identify any recurring safety incidents. These might hint at gaps in training. Review how new team members are onboarded. Are they receiving adequate guidance? Address these gaps to enhance overall safety.

Best Practices for Inventory Management in Material Handling

Efficient inventory management is critical in material handling. When items are misplaced, it leads to delays. Tracking inventory accurately minimizes these issues. Regular audits help identify discrepancies. Ensuring proper labeling is vital. Clear labels speed up picking processes.

Technology is a game changer. Barcode systems or RFID tags streamline tracking. However, not all staff may be tech-savvy. Training them can take time. There might be resistance to change, too. It’s important to address these concerns early. Handy checklists can guide workers in daily operations.

Another aspect to consider is storage organization. Utilizing vertical space can enhance efficiency. But overcrowding bins can create chaos. Striking a balance is essential. Regularly assessing storage layouts will reveal areas needing improvement. Encourage feedback from the team; they often have valuable insights.

Related Posts

-

Top Material Handling Products to Boost Efficiency in 2025

-

Top 5 Innovative Material Handling Solutions to Enhance Your Warehouse Efficiency

-

10 Essential Material Handling Tips for Increased Warehouse Efficiency

-

Top Lifting Gear Trends for 2025 You Need to Know About Now

-

Top 10 Drum Lifting Equipment Options for Safe and Efficient Handling

-

What is Drum Handling and How to Safely Manage Drums in Your Workplace