Blog

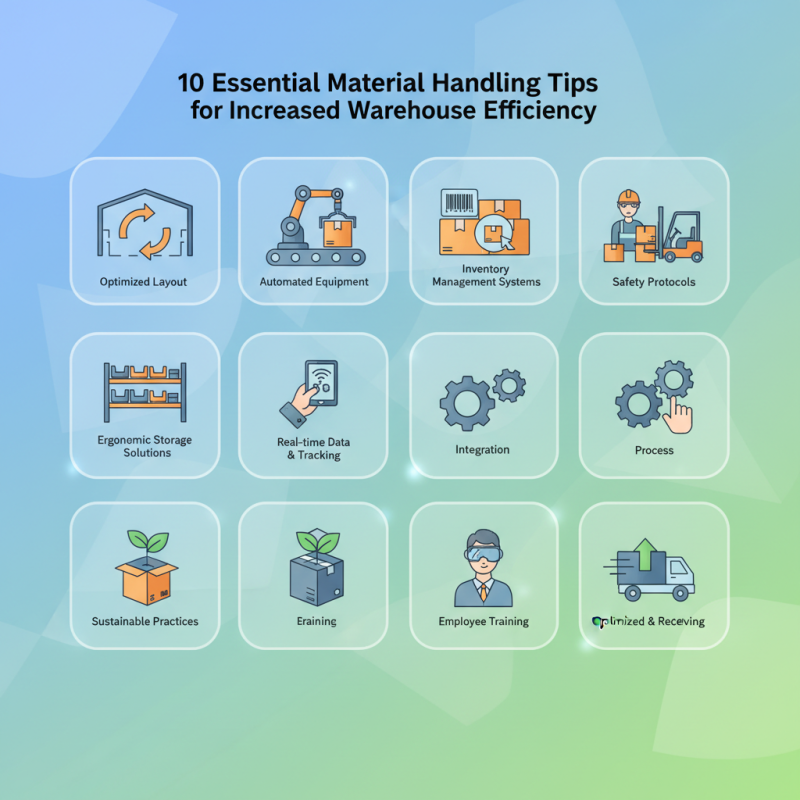

10 Essential Material Handling Tips for Increased Warehouse Efficiency

In today’s fast-paced industrial environment, optimizing warehouse efficiency has become paramount for businesses seeking to enhance productivity and reduce costs. One of the key components in achieving this goal is through effective material handling. The processes involved in moving, storing, and controlling inventory play a crucial role in the overall functionality of a warehouse. Proper material handling techniques not only streamline operations but also minimize risks, damage, and waste, ultimately leading to improved service levels and customer satisfaction.

To ensure an efficient warehouse operation, it is essential to adopt best practices that focus on enhancing material handling processes. From the strategic layout of storage spaces to the implementation of the right equipment, every decision impacts the flow of goods and the speed of order fulfillment. By addressing common bottlenecks and employing innovative solutions, warehouses can significantly boost their operational performance. This article explores ten essential tips for improving material handling, offering valuable insights for warehouse managers looking to optimize their operations and elevate their efficiency to new heights.

Best Practices for Organizing Warehouse Layout to Enhance Material Flow

Efficient warehouse layout is pivotal for optimizing material flow and ensuring smooth operations. A well-organized space allows for quick access to frequently used items, reducing the time employees spend searching for products. Implementing a zone-based system can enhance organization, where similar items are stored in close proximity, making it easier for workers to perform picking tasks. This method not only saves time but also minimizes the risk of errors when retrieving materials.

In addition to zoning, incorporating clear labeling and signage can dramatically improve navigation within the warehouse. Color-coded labels and well-defined pathways guide workers through the layout, facilitating faster movement and reducing congestion. Additionally, utilizing vertical space by installing shelving and racking systems can maximize storage capacity while maintaining an orderly flow. Regular reviews of the warehouse layout, informed by actual data on movement patterns and inventory turnover, can identify areas for improvement and adapt the layout to changing needs, ensuring sustained efficiency in material handling.

Effective Use of Technology in Material Handling for Improved Efficiency

The integration of technology in material handling processes is a crucial factor for enhancing warehouse efficiency. According to a report by the Material Handling Industry of America (MHIA), nearly 80% of companies that implemented advanced technologies, such as automated guided vehicles (AGVs) and warehouse management systems (WMS), observed significant improvements in their operational performance. These technologies enable real-time tracking of inventory and streamline picking processes, reducing the time it takes to manage materials by up to 30%. Consequently, the utilization of such tools provides businesses with the agility needed to respond swiftly to market demands.

Furthermore, adopting data analytics in material handling can facilitate better decision-making and optimization of resources. A study published by McKinsey indicates that organizations utilizing predictive analytics in their supply chain operations have seen up to a 20% reduction in operational costs. By analyzing data trends related to inventory movement, companies can efficiently plan their staffing and layout, leading to increased throughput and reduced bottlenecks in warehouse operations. The effective use of technology not only minimizes human errors but also enhances visibility and control over the entire supply chain, making it indispensable for any warehouse aiming for increased efficiency.

Strategies for Proper Training of Staff in Material Handling Techniques

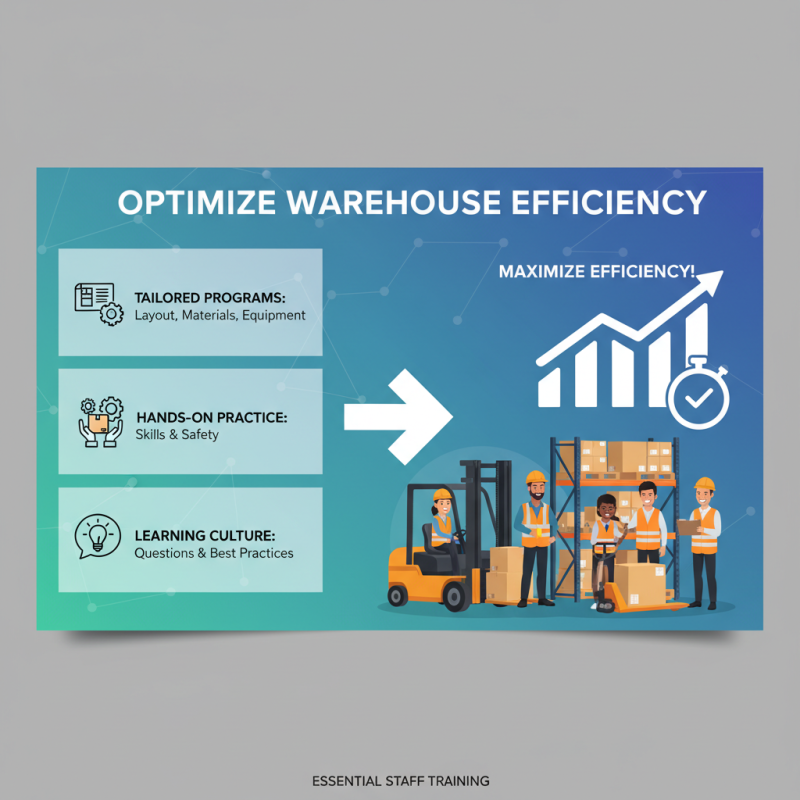

Proper training of staff in material handling techniques is essential for maximizing warehouse efficiency. To start, training programs should be tailored to the specific needs of the warehouse environment. This includes familiarizing employees with the layout of the facility, the types of materials being handled, and the equipment available. By integrating hands-on practice with theoretical instruction, workers can gain confidence and develop the required skills to handle materials safely and efficiently. It's crucial to foster a learning environment that encourages questions and discussions, allowing employees to fully understand the importance of best practices.

In addition to initial training, ongoing education and refresher courses are vital in maintaining high standards of material handling. Regular training sessions help employees stay updated on new techniques, safety protocols, and advancements in equipment. Incorporating assessments and practical evaluations can ensure that staff members are effectively applying what they have learned. Furthermore, creating a mentorship program where experienced employees guide newcomers can enhance skill transfer and reinforce a culture of safety and efficiency. By prioritizing comprehensive training initiatives, warehouses can significantly reduce the risk of accidents and inefficiencies, ultimately leading to improved overall productivity.

Implementing Safety Protocols to Minimize Risks in Warehousing Operations

Implementing safety protocols in warehouse operations is essential to minimize risks and ensure a

secure working environment. With the fast-paced nature of warehousing,

where employees handle heavy materials and navigate through tight spaces, safety protocols help reduce accidents and injuries.

Regular safety training sessions should be implemented, ensuring all employees are aware of proper lifting techniques, the use of

personal protective equipment (PPE), and the importance of maintaining a clean workspace.

Establishing clear guidelines for equipment operation and setting designated walkways can further enhance safety.

In addition to training, warehouses should conduct frequent safety audits to identify potential hazards and areas for improvement.

Implementing signage and reminders throughout the facility can reinforce safety practices and alert staff to any immediate dangers.

Emergency procedures and contact information should be easily accessible to all employees, enabling a swift response in case of incidents.

Encouraging a culture of safety where employees feel empowered to report unsafe conditions

can significantly reduce the likelihood of accidents, ultimately contributing to increased efficiency in warehouse operations.

Optimizing Inventory Management to Streamline Material Handling Processes

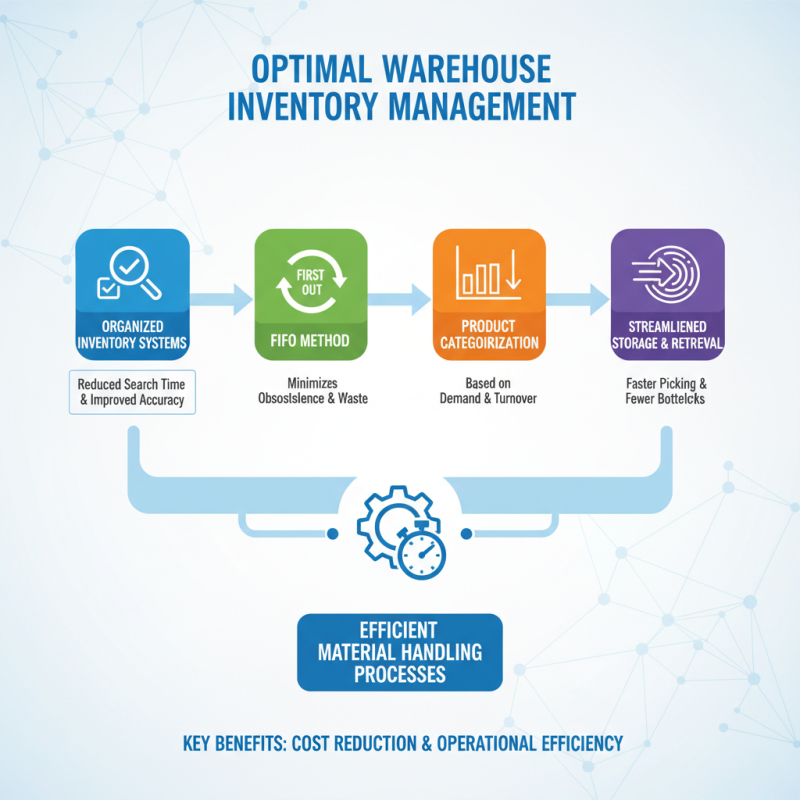

Effective inventory management is crucial for optimizing material handling processes within a warehouse. By implementing organized inventory systems, businesses can substantially reduce the time spent searching for items and improve overall accuracy in stock levels. Utilizing techniques such as First In, First Out (FIFO) ensures that older stock is dispatched before newer inventory, thus minimizing the risk of obsolescence and waste. Furthermore, categorizing products based on demand and turnover rates helps streamline storage, allowing for faster retrieval and minimizing bottlenecks during picking operations.

Another critical aspect of inventory management is the use of technology to enhance visibility and control. Implementing automated tracking systems, such as barcode scanning or RFID technologies, allows for real-time monitoring of stock levels. This not only aids in maintaining optimal inventory levels but also assists in forecasting needs more accurately. By integrating advanced software solutions for inventory management, warehouses can achieve better data analytics, leading to informed decision-making for purchasing and restocking. Such enhancements in tracking and analytics minimize errors and ensure that material handling processes are both efficient and reliable.

Related Posts

-

Top Material Handling Products to Boost Efficiency in 2025

-

Top 5 Innovative Material Handling Solutions to Enhance Your Warehouse Efficiency

-

Top 10 Best Material Hoists for Efficient Construction Projects in 2023

-

10 Essential Tips for Choosing the Right Industrial Lifting Equipment

-

What is the Best Lifting Tools for Your Needs and How to Choose Them

-

Top 10 Drum Lifting Equipment Options for Safe and Efficient Handling